What is a slurry pump? When I first entered this industry, I also wanted to understand this immediately, but unfortunately, the answers I found online were too simplistic.

Today, I will provide a comprehensive explanation of what a slurry pump is, covering its principles, uses, structure, and manufacturing process.

I. Principle of Slurry Pumps

Slurry pumps, in principle, belong to the category of centrifugal pumps.

Their principle is based on the transfer of mechanical energy from the prime mover to the liquid through the action of the rotating impeller on the liquid.

As the liquid flows from the impeller inlet to the outlet, both its kinetic energy and pressure energy increase. The liquid discharged by the impeller then passes through the volute casing;

Most of the kinetic energy is converted into pressure energy, and then the liquid is transported along the discharge pipeline;

At this point, a vacuum or low pressure is created at the impeller inlet due to the discharge of the liquid;

The liquid in the suction pool is forced into the impeller inlet by the pressure at the liquid surface (atmospheric pressure);

Consequently, the rotating impeller continuously draws in and discharges the liquid.

Note: Slurry pumps are generally designed for flooded suction, meaning the liquid level is higher than the pump’s horizontal position, and the submersible slurry pump is submerged below the liquid surface.

II. Applications of Slurry Pumps

Slurry pumps have a wide range of applications, mainly providing supporting pumps for industries such as mining, metallurgy, municipal engineering, power generation, coal mining, dredging, flue gas desulfurization in thermal power plants, petroleum, chemical industry, building materials, papermaking, and pharmaceuticals.

They are used for transporting slurries containing solid particles.

The demand is particularly high in metal ore processing and coal preparation.

III. Slurry Pump Structure

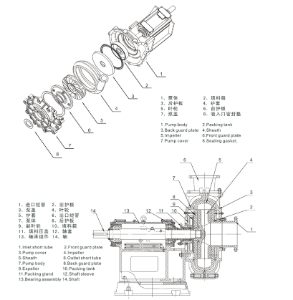

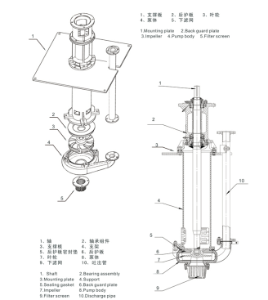

Slurry pumps are mainly divided into two types based on their structure: horizontal slurry pumps and vertical slurry pumps, among which vertical slurry pumps are generally submersible slurry pumps.

Our company’s ZJ, ZGB, AH, HH, M, and L series slurry pumps, as well as dredging pumps and desulfurization pumps, are all horizontal slurry pumps.

SP and ZJL series slurry pumps are vertical slurry pumps.

Horizontal Slurry Pump Structure Diagram:

Schematic diagram of a vertical slurry pump structure:

IV. Slurry Pump Manufacturing Process

The core components affecting the quality of slurry pumps are the flow-through parts, including: casing (volute, pump body), impeller, and wear plate.

Some users may use different terminology; for example, the wear plate may be called a liner, and the volute may be called an inner casing.

Today, we will mainly explain the manufacturing process of the flow-through parts of slurry pumps.

The complete manufacturing process of slurry pump flow-through parts includes: casting, heat treatment, and machining.

Casting is fundamental and is the basic factor determining the quality of slurry pump components; the metal element content of the material depends on this.

Heat treatment is crucial, and it is divided into normalizing (hardening) and annealing (softening).

Normalizing primarily eliminates internal stresses to achieve the required working hardness.

Annealing is mainly performed to soften the material for subsequent machining.

Machining involves using a lathe to process the raw castings of the slurry pump’s flow-through components to the required installation dimensions. This production process must be strictly controlled.

Otherwise, it will directly affect the installation and use of the slurry pump.

发表回复