Understanding the significance of the operating point of a slurry pump is crucial for proper pump selection, enabling us to choose the most suitable pump type for our customers.

The operating point is very important, and all professionals in the slurry pump industry should understand this basic knowledge.

I. Definition of Slurry Pump Operating Point

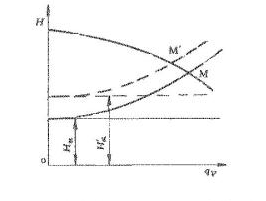

The operating point of a slurry pump is the same as that of a clean water pump; it is the intersection point of the pump’s slurry performance curve and the pipeline’s slurry characteristic curve.

The slurry performance curve of the slurry pump can be obtained through the head ratio.

II. Factors Affecting the Operating Point

Due to the wear of the wetted parts when the slurry pump is transporting abrasive slurries, the pump’s performance will decrease accordingly;

The operating point will also gradually shift along the pipeline characteristic curve from high flow rate to low flow rate;

Therefore, it can be seen that the operating point of the slurry pump (except for variable speed operation) is constantly changing, with the flow rate decreasing and the head decreasing.

III. Considerations when selecting a slurry pump

To ensure that the slurry pump operates near its rated operating conditions for an extended period, a certain head margin is often added during pump selection;

This means that the flow rate and head at the operating point during the initial operation of the pump will be higher than the rated operating conditions.

Schematic diagram of slurry pump operating conditions:

发表回复